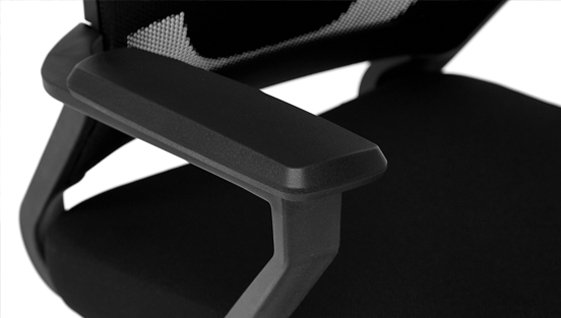

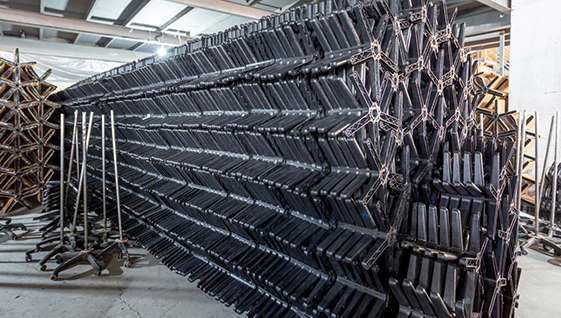

Injection molding is a high-efficiency, precision molding process that involves heating synthetic resin (plastic), injecting it into a mold, and cooling it to form the desired shape. By rigorously controlling injection temperature, pressure, and cooling time, parts are produced with outstanding strength and stability. This equipment allows us to mass-produce components for plastic chairs, office chairs, and designer chairs.

R&D Center

We offer flexible ODM and OEM services to meet diverse customer needs, quickly transforming ideas into tangible products, supporting sample provision, custom colors, specifications, and large-scale production.

From mold development to structural strength analysis, every component detail undergoes repeated testing and refinement, ensuring chair parts are lightweight while maintaining superior load-bearing capacity and durability.

We implement strict standards and regulations for raw material selection, production, and assembly processes. Although the industry is relatively young, we lead by example, setting new benchmarks for the chair component supply sector.

Quality Control

A five-stage quality inspection process spans the entire production cycle, ensuring every product meets high-quality standards from raw materials to finished goods.

-

Raw Material Inspection

Raw Material InspectionCarefully selected materials that are eco-friendly, safe, and stable in performance.

-

Sample Testing in Trial Production

Sample Testing in Trial ProductionVerifying design accuracy and functionality.

-

In-Process Inspection

In-Process InspectionReal-time monitoring of craftsmanship and product quality.

-

Finished Product Testing

Finished Product TestingEnsuring the appearance, performance, and stability of the final product.

-

Final Pre-shipment Inspection

Final Pre-shipment InspectionGuaranteeing all products meet customer and international standards.

-

Multiple Injection Molding Machines Enable Efficient and Precise Production of Plastic Components

Multiple Injection Molding Machines Enable Efficient and Precise Production of Plastic Components -

A Dedicated Upholstery Production Line Focuses on The Manufacturing of Office Chairs and Upholstered SeatingThe production of upholstered and office chairs involves complete procedures from cutting fabric and foam, and processing frames, to assembling the final product. Our production line, comprising eight stages and 50 skilled workers, ensures that each chair is meticulously crafted to be both comfortable and visually appealing.

A Dedicated Upholstery Production Line Focuses on The Manufacturing of Office Chairs and Upholstered SeatingThe production of upholstered and office chairs involves complete procedures from cutting fabric and foam, and processing frames, to assembling the final product. Our production line, comprising eight stages and 50 skilled workers, ensures that each chair is meticulously crafted to be both comfortable and visually appealing.

En

En

Español

Español